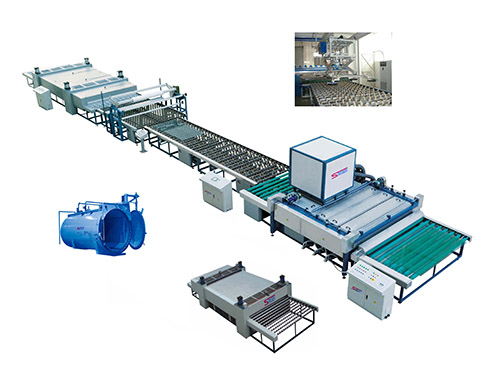

Silicone vacuum bag helps to pump out the air between glass and EVA film, will fix the two glass

on the right position to avoid the error. CASIS can provide ordinary, medium and high grade tear

resistance silicone blanket to produce vacuum bag according to the different requirements of users.

This vacuum bag is useful for the glue adhesion when the EVA film start to melt after fixed glasses.

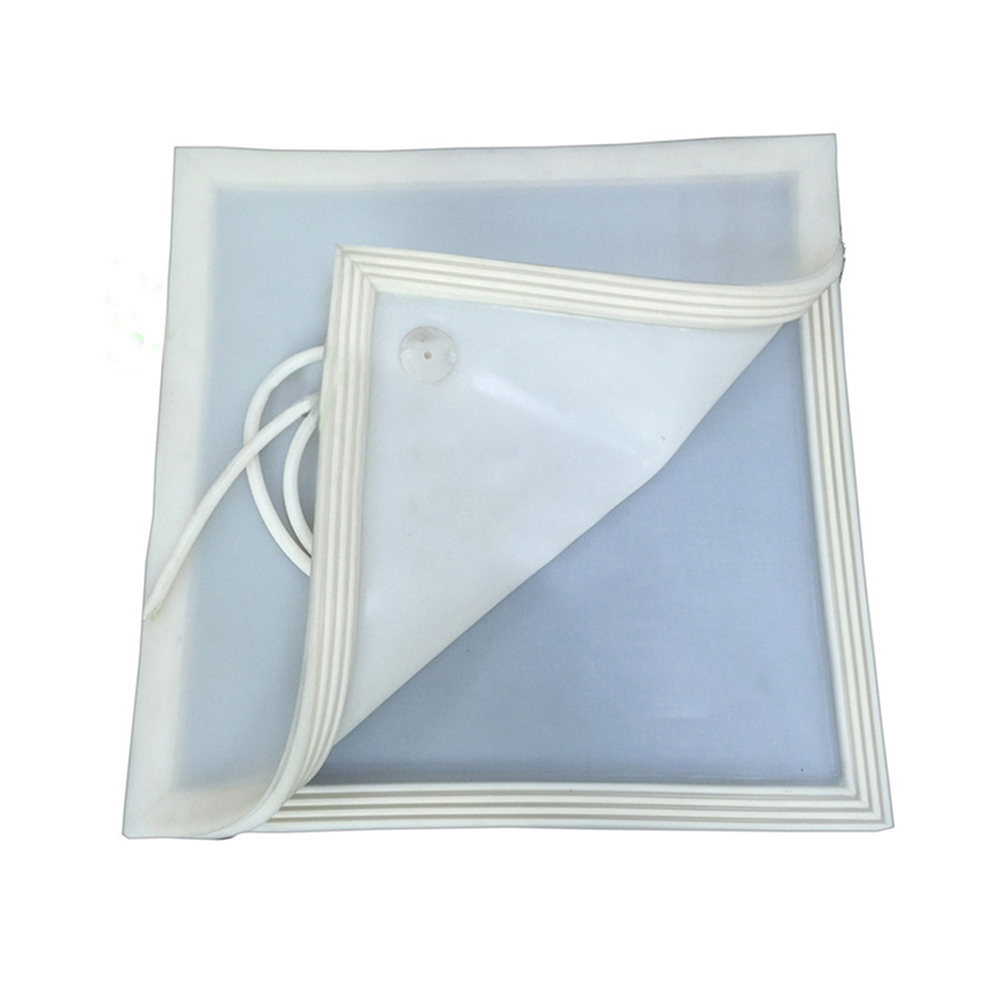

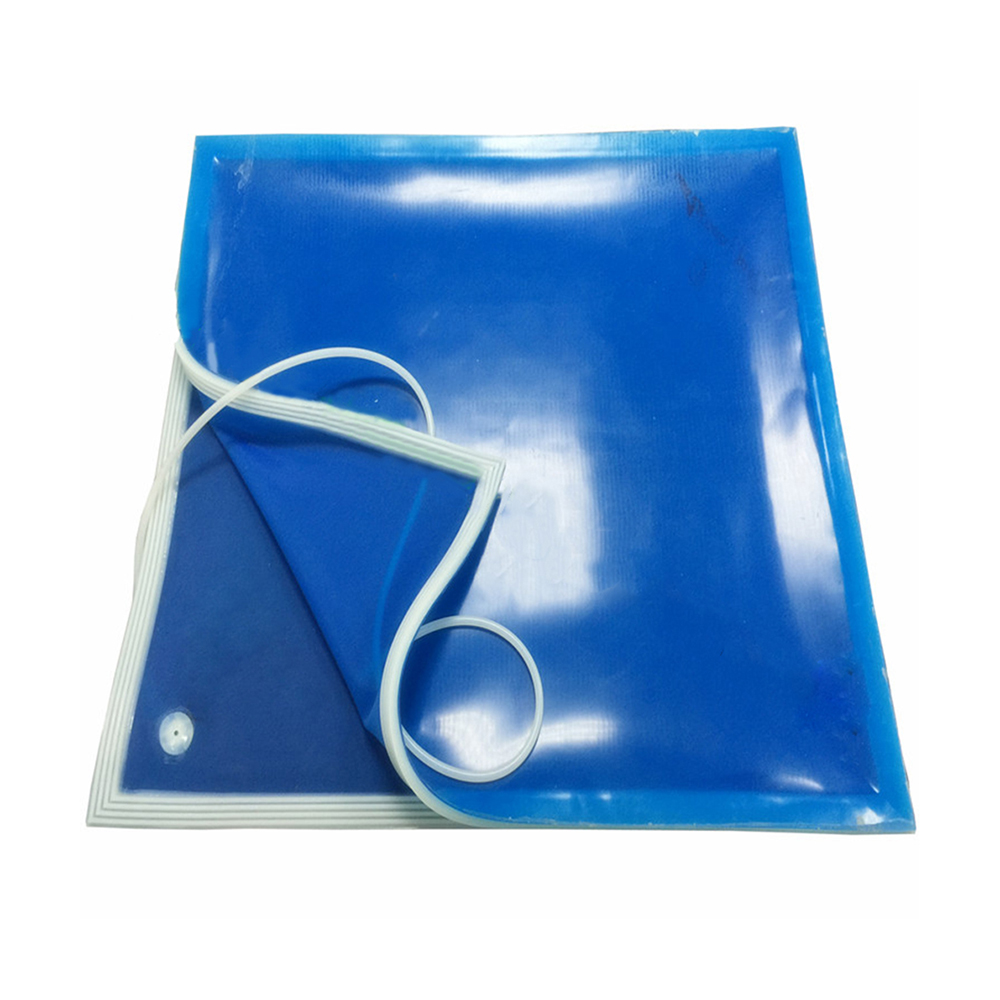

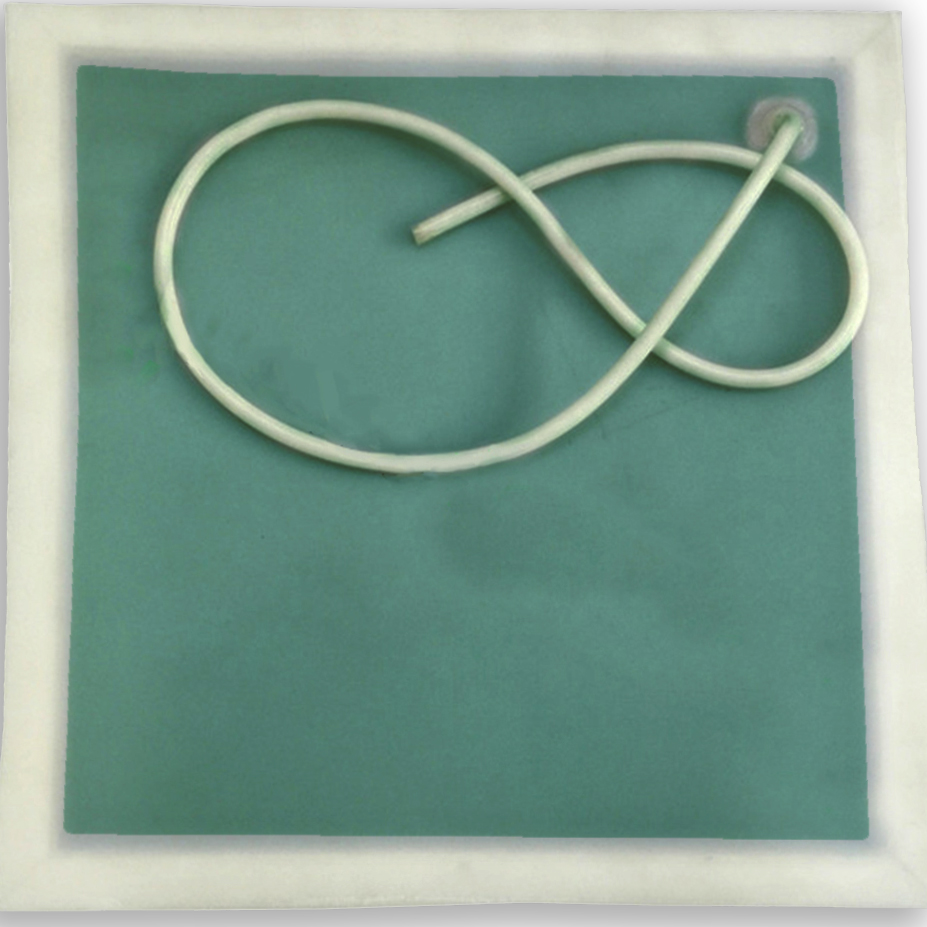

It is high heat-resistance. Each bag includes silicone sheet, buckle and nozzle, tube and other accessories.

> OUTSTANDING FEATURE

Three different grades of tear resistance are available.

Mountain shaped silicone sealing strip are available for edge of vacuum bag.

High temperature resistance to 250℃, Great aging-resistance and resistance to EVA.

Maximum widths up to 3800mm are available without joining.

No bubbles or opaqueness are noted in the spacer in any sample tests of the laminated glass.

Connecting vacuum pump, pump out the air and keep the air pressure well during lamination.

DIVERSE CHOICE FOR MATERIAL

SPECIFICATION

WORKING PRINCIPLE :

Laminated glass vacuum furnace is a special equipment that adopted the vacuum principle, make the glass heated under vacuum conditions, using atmospheric pressure inside the vacuum bag glass pressurized air leaving it unable to rule out the bubbles, while heating under vacuum in the vacuum conditions, the two or more pieces of glass, EVA (or other membrane) heat together to make glass compression, let the EVA film melt under high temperature condition, then can be that let the laminated materials (such as silk, and paper, cloth, drawing paper, etc.) and glass glue together firmly, to form a whole-part, To achieve the purpose of explosion protection, security, decorative and practical. As the core component of Laminated glass reinforced furnace, the vacuum bag affects the quality of the glass products. Products are mainly used to strengthen the glass, sliding door glass, laminated safety glass for vacuum using.

DESIGN PRINCIPLE:

Durable & Flexible Silicon Blankets

This strong silicone blankets meets the most severe industrial tests. It is made of special high temperature resistant silicon. The material will not become brittle after numerous heating and cooling cycles. It is resistant to high pressure forces when wrapping around glass during vacuum.