| Parameter | Details |

|---|---|

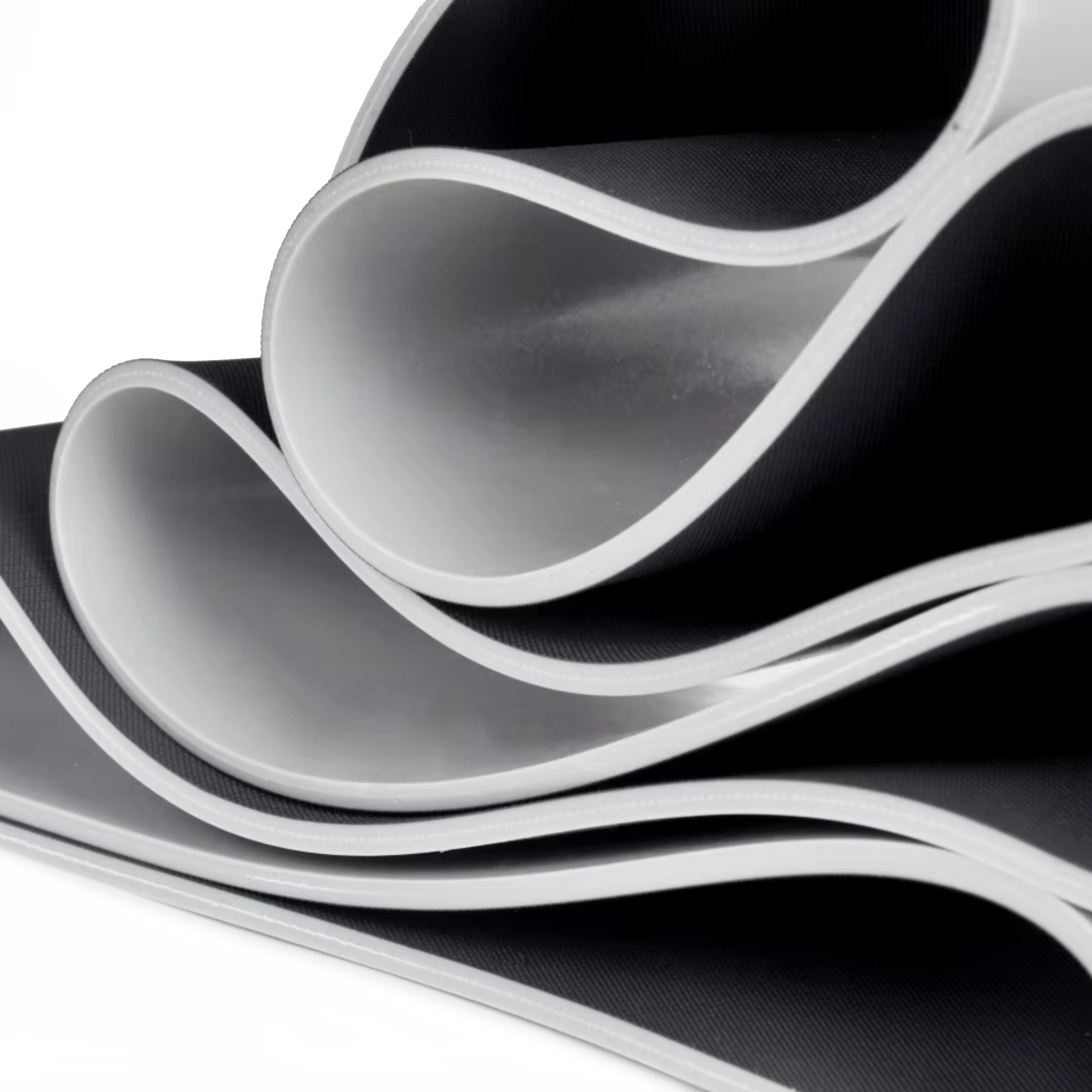

| Product Name | KS-EXR268 Silicone Membrane |

| Applicable Industries | Photovoltaic field |

| Use for | Solar laminator |

| Material | Silicone |

| Insertion | with fabric insertion |

| Surface | Smooth/Rough, Smooth/Smooth |

| Colour | Grey/Grey, Blue/Blue |

| Test Standard | GB, ASTM |

| Max Width | Close to 3,780mm without seam |

| Product Advantage | KS-EXR268 series is our product for PV module manufacturer, We use the insertion technology to make the various performance of KS-EXR268 has been a improve dramatically, especially the tensile strength & tearing strength. In 2014, after our continuous adjusted new technology we used the KEVLAR from American DuPont Company instead of the traditional fabric, so now KS-EXR268 series products will be sturdier, the service life time can reach more than 6000 times for dual-chamber(cavity) machine. |

World-wide producers of thin film and crystalline solar panels face corrosive attacks on Silicone Sheets used on lamination equipment.

During the lamination / encapsulation process of EVA volatile outgassing occurs. Outgassing refers to unwanted chemicals that are usually a bi-product of the process and temperature. These acidic fumes are emitted from adhesive or other components and can lead to corrosion of the Sheets. This corrosion manifests itself in surface degradation (cracks) + excessive stretching and sagging.

But KS-EXR268 series solves all the above problems well, because It’s a composite material that resists the deterioration caused by EVA outgassing. In addition it is a really tough material with both tensile strength and tear resistance higher than traditional Membranes materials. This makes Lamination particularly durable and increases your machine running times.

Besides,KS-EXR268 series has very tight elongation features – resistant to excessive stretching and sagging. Customers’ feedback indicates that this series may give up to 50% longer life than some traditional Diaphragm materials – obviously dependent upon type of module, encapsulant and conditions.

Membranes FAQs

What’s the best silicone membrane for solar modules lamination?

This is really a vital question and can be best discussed together face-to-face. There is no one answer that is right for everybody. There are many determining factors that can affect the choice of silicone membranes. For example type of encapsulant, the composition of the modules, size of the modules, a brand of laminator, and budget constraints, etc.

How long should a silicone membrane last?

Commonly our data shows that KS-EXR268 – 6,000 cycles for dual-chamber(cavity) machine + KS-EXR668 – more than 12,000 cycles for dual-chamber(cavity) machine.. As there are a number of variables beyond our direct control, it is very difficult to “guarantee” an exact cycle life.

Does color or surface finish have any impact on membrane performance?

Based on feedback from customers worldwide, we can see no advantage or disadvantage of different colors, or indeed surface finish. Actually, colors are now used to differentiate between suppliers.

How can we tell the difference of Casis solar silicone membranes?

As technology progresses, there are three types of silicone membranes for the solar industry. Please check or download below technical data sheet for your further distinction.

![]() Technical Specifications – KS-EXR668 Series

Technical Specifications – KS-EXR668 Series ![]() Technical Specifications – KS-EBS468 Series

Technical Specifications – KS-EBS468 Series ![]() Technical Specifications – KS-EXR268 Series

Technical Specifications – KS-EXR268 Series

How long should a diaphragm last?

This also depends on your encapsulant and type of module. Give us a call or email to talk about your product and processes to determine what you should be getting from your membrane.

What can we do to extend the life of our membrane?

Consider protecting it with a layer of PTFE sheet between the modules and the membrane. We have several options for this. And if you’re encapsulating with EVA, we should recommend KS-EXR268 Silicone membrane that is resistant to the outgassing from the EVA. The KS-EXR268 option may give you far better life than your current membrane.