VERY SIMILAR TO NITTO EPTSEALER EE1000 SERIES ( THE MOST POPULAR PRODUCT ITEM )

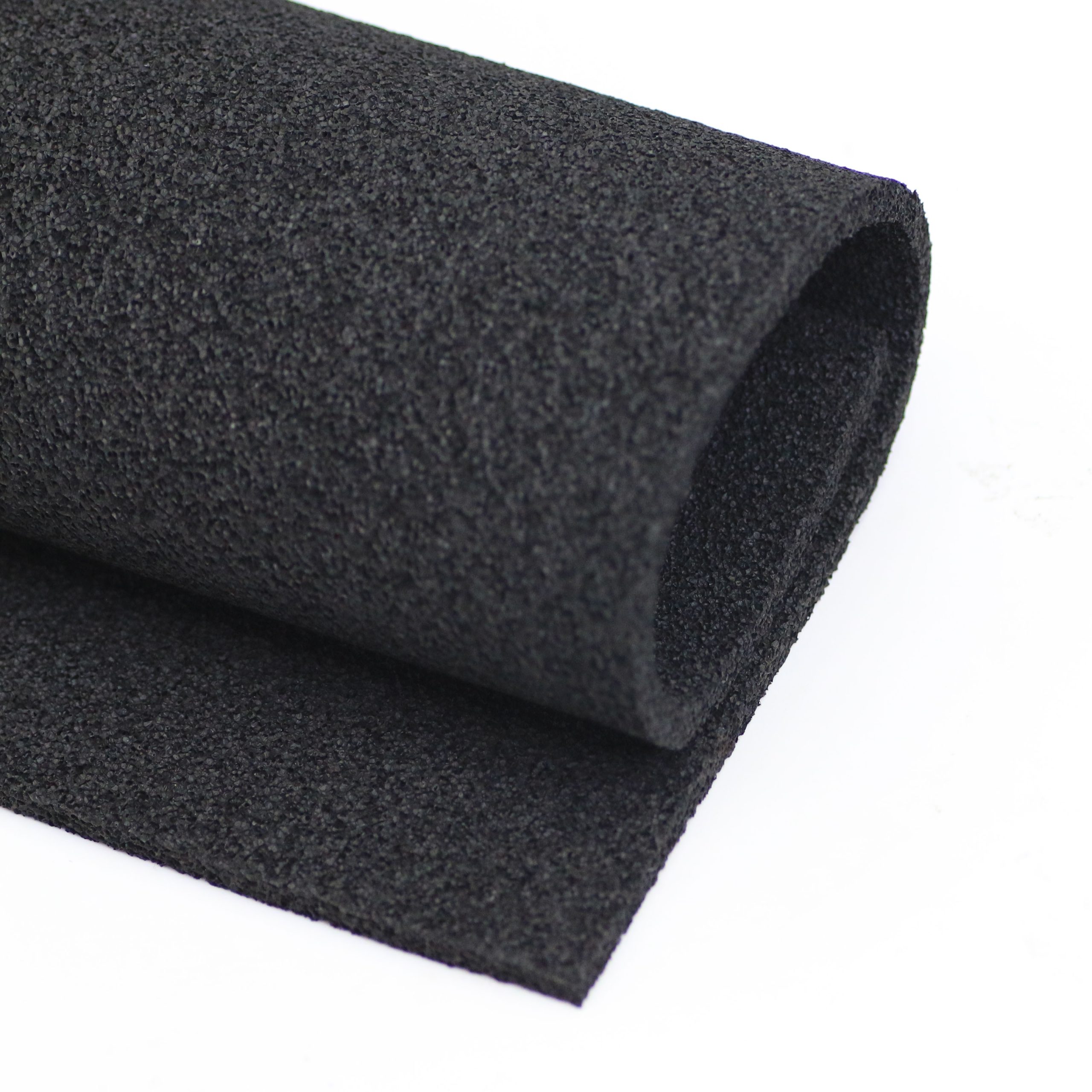

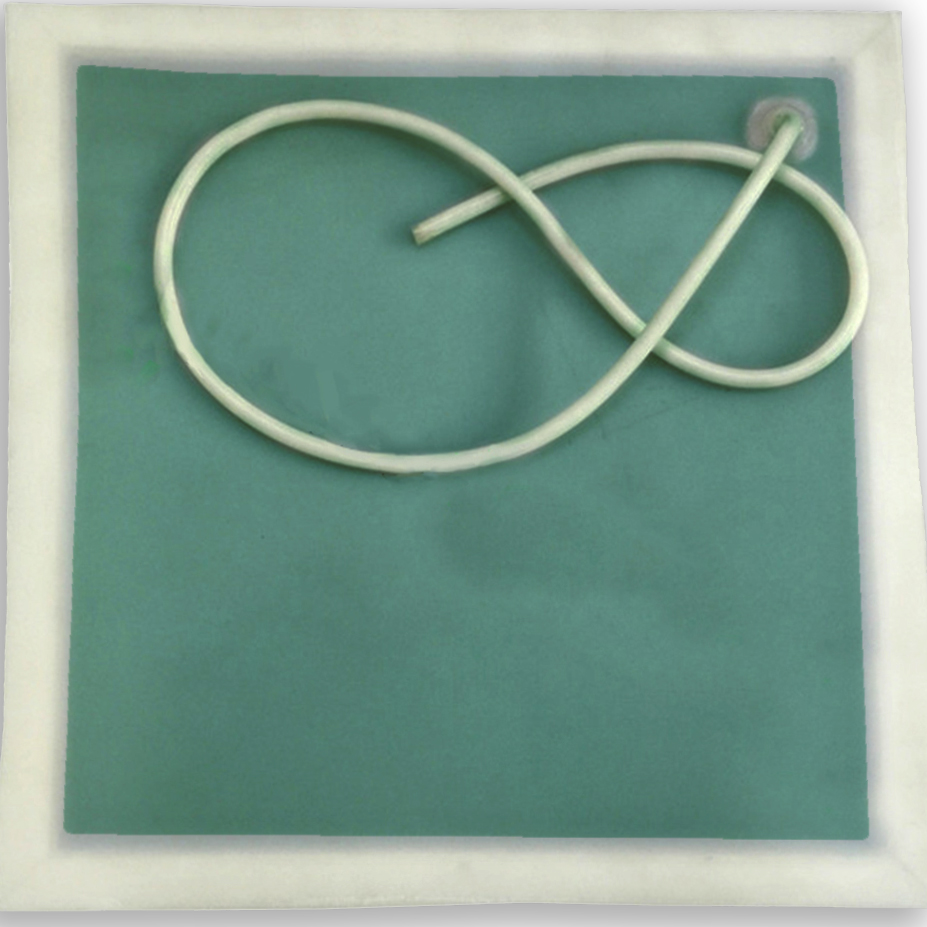

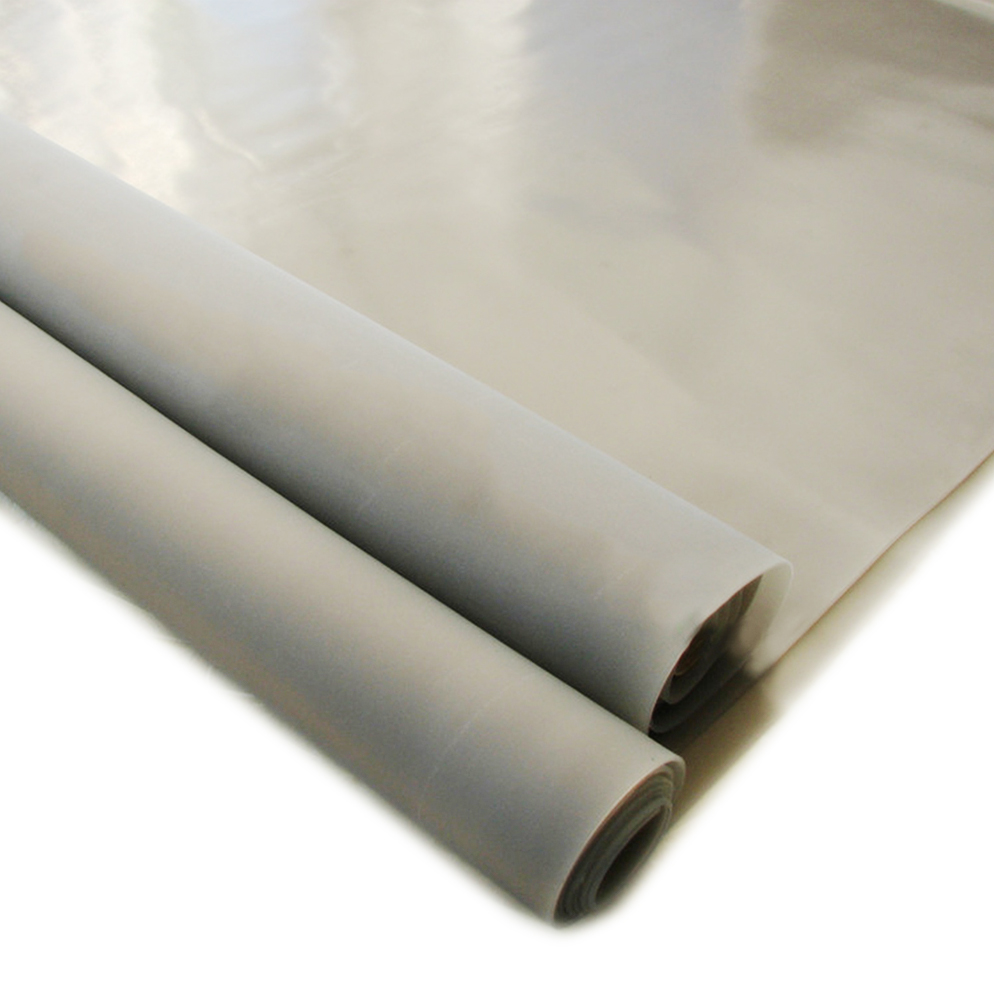

> OPEN CELL EPDM /SEMI CLOSED CELL

Foam sealing material with superior resistance to weather, cold, heat and chemicals.

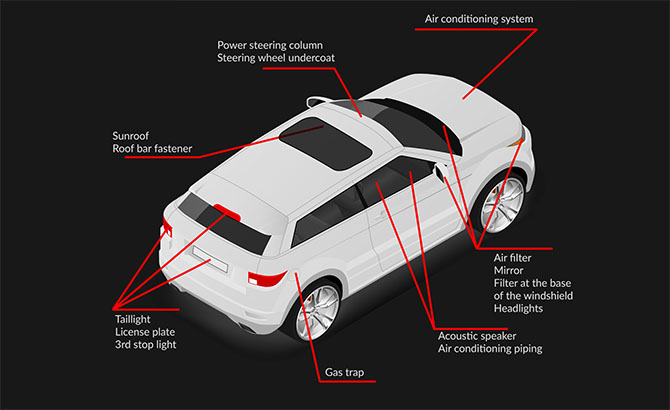

> CASIS ATRIES foam sealing material to fill cavities of various types of equipment,

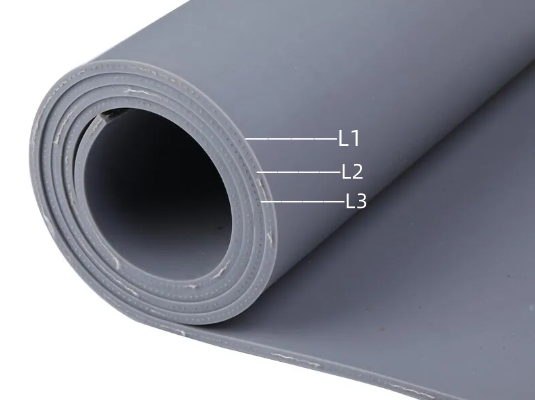

consisting of EPDM synthetic rubber foam with a semi-closed cell structure. Higher

compression foams are available for variouspurposes such as waterproof,windproof,

dust-proof, soundproof, or thermal insulation according to the compression ratio.