> PRODUCTION TECHNOLOGY

> a. Custom Molded Silicone Products

The manufacturing processes adhere to many industry standards, such as FDA 26CFR, ISO 9001:2015,ASTM, and so on. Main products including: gaskets, inflatable seals, sheeting, hoses, bellows,O-ring, etc for common. We can also develop unique formulations to meet specific application requirements.

> b. Custom Extruded Silicone Products

In addition to custom molded silicone parts, CASIS offers a wide variety of extruded silicone for profiles, sealings, gaskets, cords, hose, and insulation. These rubber extrusions have a specific cross-sectional shape and are either solid or hollow. It supports a rich variety of colors compared to other rubber materials.

WE CAN CUSTOMIZE

SPECIFICATION

Material Advantage:

Thermal stability , insulation from electricity, seal formation, compression set resistance, corrosion resistance, weather resistance, sound and vibration dampening. It’s resistant to water, oils, solvents, and other chemicals, when burned, almost no black smoke or noxious gas is produced during combustion. It’s also compatible with FDA regulations and can undergo many different sterilization techniques.

Custom Silicone Parts for Specific Markets:

Because custom silicone has become a popular option for addressing the extreme operating conditions found across many major industries. Its properties that other organic rubbers just cannot match. The manufacturing processes adhere to many industry standards, such as FDA 26CFR, ISO 9001:2015, ASTM, and so on. Main products including: gaskets, inflatable seals, sheeting, hoses, bellows etc for common. We can also develop unique formulations to meet specific application requirements.

Silicone Rubber Key Features:

Extreme temperature resistance (from -70°C to +300°C)

Excellent resilience to weathering and environmental influence

FDA approved compounds

Good electrical insulation properties

Mechanical damping properties

Good rebound and recovery

Fire retardant to EN45545-2 grades

Repels water providing tight sealing solutions

Metal detectable range

Can be produced in various colours

We are constantly working with compounders and in the laboratory to formulate new silicone rubbers and exceed performance expectations. All of silicones fantastic features are why so many of our partners use it in their industry.

Applications & Industries :

Food industry – FDA compounds

Medical & Pharmaceutical

Rail & transport industry – to EN45545

Marine & Super yacht

Aerospace

Construction

Electrical & Lighting

Offshore Industry

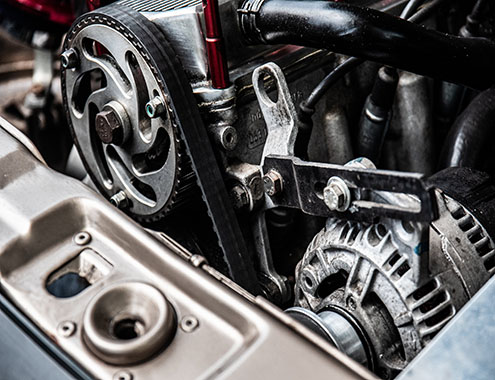

Automotive

About Customizations :

Our Technical staff are available for expert guidance and help in determining the design, material selection and availability of the product, to give you the optimum advice and choice. CASIS can provide customers with all-around rubber solutions, including product R&D, product design, material recommendation, customized and service. We have an own new materials subordinate institute. We regularly cooperate with universities to analyze and research new materials, and match better rubber formulas to their required fields to help customers solve more technical bottlenecks and obstacles.