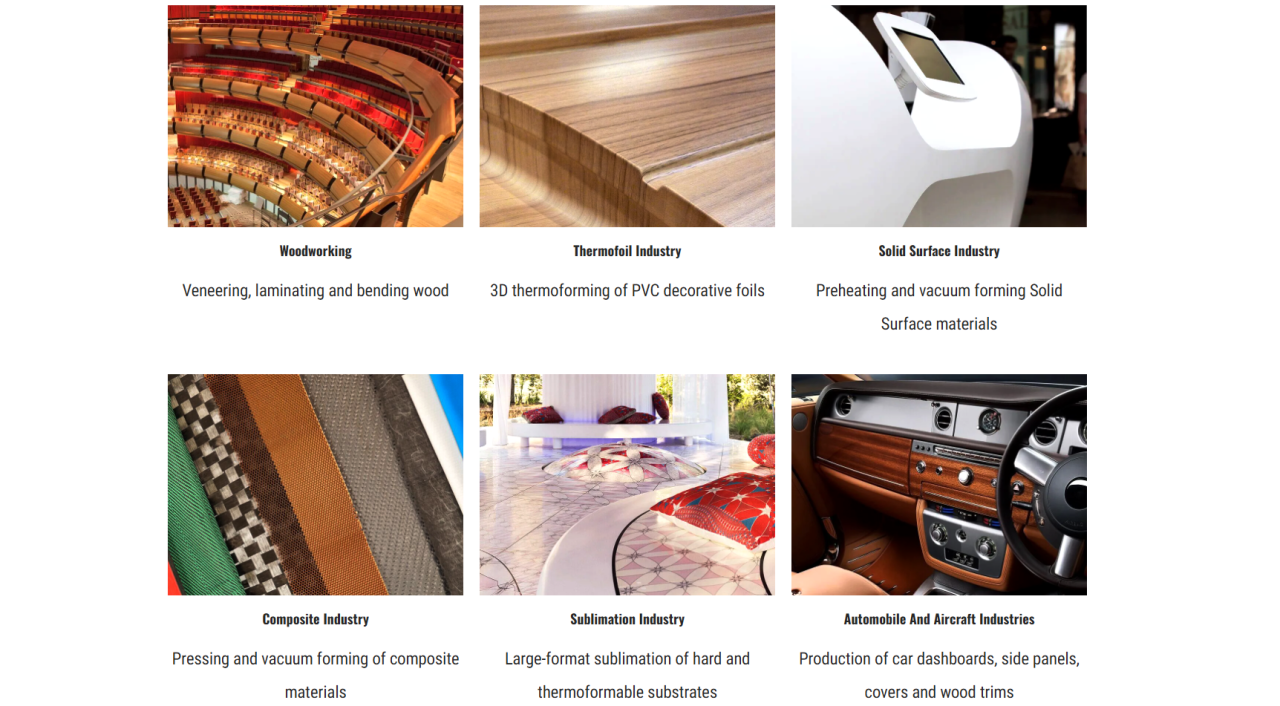

> Vacuum Pressing Membranes For Thermoplastic Composite Forming and Woodworking :

They are also called vacuum membranes or silicone membranes, and is mainly

used for woodworking vacuum presses in bending, forming, laminating and veneering

flat and curved surfaces. It has the ability to withstand high and low extremes with its broad

working temperature range. Different hardness levels as well as smooth or textured finishes

are available, ensuring that each customer can find the suitable membrane for their application

in veneer pressing, wood bending, and composite lamination.

> The following are some common applications of vacuum pressing membranes in the

woodworking industry :

Thermoforming of acrylic solid surfaces ( Corian, Hi- Macs, Staron, Hanex, Avonite, Krion, etc )

Forming of thermoplastics ( Acrylic, ABS, PVC, PET-G, etc )

Bending of MDF/ Plywood, Laminating of veneers, etc.

Thermofoil of MDF/wood

KS-EXC61 VACUUM PRESSING MEMBRA

OUTSTANDING FEATURE

> Silicone membranes offer superior strength and elasticity with an extremely high working temperature range.

> Silicone membranes can be used for membrane presses with positive or negative pressure.

> Silicone membranes can be used for laminating of PVC foil, wood veneering, bending of wood, MDF, shaping and thermoforming of solid surfaces and thermoplastic materials.

> Thermoforming of solid surface materials (Corian/Staron/Hi Macs/Hanex/Kerrock)

> Forming of composite materials and plastics.

> Laminating of veneers, leather and paper. Foiling of PVC film. Bending and gluing of furniture parts.

> Silicone membranes can have both sides smooth or one side cloth impression surface finish.

SPECIFICATION

Thermoplastic Composite Forming specialized silicone plate is a kind of silicone film that can form different shapes under high temperature and high pressure, it is mainly used in the following aspects:

- PVC laminating: laminating PVC film on wood, metal or other materials, making surfaces with different colors, textures and waterproof performance.

- Wood veneering: laminating wood veneer or other decorative materials on wood or artificial board, making furniture, door panels or floors with different appearance and texture.

- Wood bending: heating and softening wood or artificial board, using the pressure of silicone film to bend it into different curves, making furniture, musical instruments or artworks

with different shapes.

- Solid surface and thermoplastic material forming and thermoforming: heating and softening solid surface (such as artificial stone, acrylic, etc.) or thermoplastic material (such as

ABS, PVC, PET-G, etc.), using the pressure of silicone film to form or thermoform it into different three-dimensional shapes, making products with different functions and aesthetics.

Applications of Highly Elastic Silicone Membranes

The vacuum pressing membranes are used in the production of wood veneers and thermofoil door panels for industry leaders who demand quality silicone. Our long history working

with them has helped us develop a reputation as a reliable supplier, always producing top-quality silicone rubber membranes that you can trust to do what they were designed for –

protecting your projects from damage caused by temperature changes or dampness.

CASIS silicone pressing membrane can be well compatible with GLOBAL, ADAMIK, ARTEX, BYT, BARTH, BUGATOOL, ELKOM, ISTRA-A, ORMA, RIBEX, WISCHT, Vac-U-Clamp,

etc to ensure your equipment is operating to its full potential and capabilities. This kind of product is an excellent choice for many industries and will provide you with the protection

your business needs. Take a look at some of our applications and choose the right silicone membrane for you needs.

Silicone membrane with single-sided textured surface

Textured silicone membrane can be widely used for vacuum forming solid surface materials, thermoplastics such as acrylic, PVC, and are also suitable for wood/MDF door and

furniture 3D foil lamination. Because of its high temperature resistance and textured finish, the membrane has proven to be the superior choice for vacuum heat presses, where

continuous air evacuation is needed.

Customers can either order different sizes based on their working area, or choose from the common sizes as below, we can also do custom size cutting for you.