GBL-600S Viton Rubber exhibits rapid curing, excellent mold release, and anti-contamination properties. It also demonstrates outstanding resistance to permanent compression deformation without the need for post-curing or with short post-curing times. These characteristics make it perform well in the mentioned application areas. Here are some key characteristics of the GBL-600S:

> Chemical Composition: It’s a copolymer of hexafluoropropylene, vinylidene fluoride, and tetrafluoroethylene with a cure site monomer.

> Appearance: It has an off-white color without carbon black.

> Mooney Viscosity: ML 1 + 10 at 121 °C (250 °F) is 65, indicating its flow properties under pressure. Specific Gravity: It has a specific gravity of 1.84.

> Fluorine Content: Approximately 68%, which contributes to its chemical resistance.

> Storage Stability: The product has excellent storage stability.

DUPONT GBL-600S VITON RUBBER

SPECIFICATION

Features: This product has a very fast cure rate, achieving a high state of cure. It shows improved mold release/mold fouling characteristics compared to Viton™ GBL-200. It also exhibits improved mold flow, lower shear sensitivity, and lower extrusion die swell for a 65 Mooney FKM.

Physical Properties: The GBL-600S has excellent physical properties, with high elongation both initially and after aging. It has similar resistance to heat, fluids, and low temperatures as Viton™ GBL-200.

Compression Set Resistance: It has excellent resistance to compression set, whether it’s a short-term (2 hours) post-cure or without post-cure.

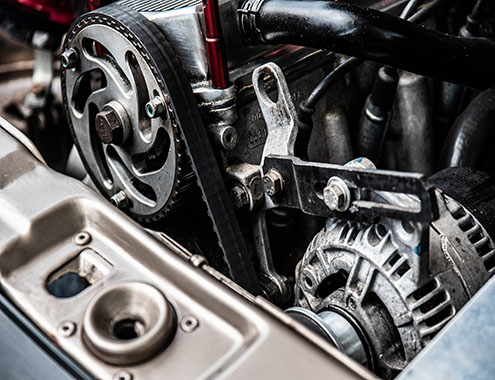

The GBL-600S Viton Rubber is a high-viscosity peroxide-cured fluoropolymer adhesive with excellent low-temperature performance and improved resistance to automotive lubricants and fluids. Its application areas include:

> Engine crankshaft and camshaft rubber seals.

> Valve stem and cover elastomeric seals

> Turbocharger hoses

> Fuel injector O-rings

> Intake manifold gaskets

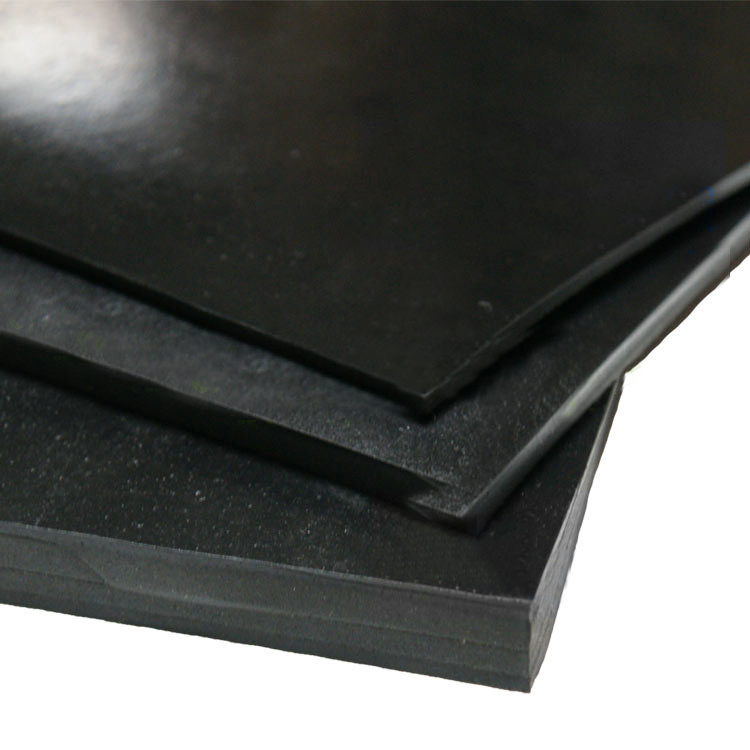

> Gaskets, O-rings, diaphragms, and rubber components

> Molded parts requiring low-temperature flexibility

It’s designed for easy processing and cures exceptionally fast to a high state of cure. It also exhibits improved mold release and mold fouling properties compared to other grades. The GBL-600S is recommended for applications requiring high elongation, both original and aged, and it exhibits similar heat, fluids, and low-temperature resistance compared to other Viton™ grades.